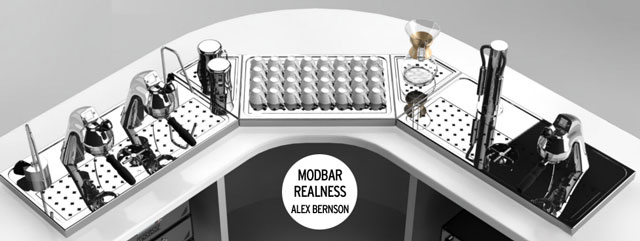

What you are currently looking at is one possible installation of the Modbar modular espresso system. Yes, that is really all that sticks out above the counter. The espresso, steam and pour-over are all self-contained “taps” that are paired to separate under-counter modules, installable in any configuration you can imagine. For the last year, Modbar has been operating as an agile startup shrouded in total secrecy, and the time has finally come to show their revolutionary new under-counter modular espresso and pour-over brewing system to the world. I highly suggest you go check it out at Counter Culture Coffee’s booth #892 on the SCAA show floor—I haven’t had the chance to go hands on yet, but if they manage to deliver on what they’re claiming, this machine could open up radical new design and service possibilities for the high-end coffee market.

The four things you need to know about the Modbar system are:

1. Espresso, steam and pour-over modules can be purchased and inter-connected in any number and configuration you want.

2. It takes five minutes for the espresso module to go from turned off to full operating temperature.

3. The slender above-counter tap profile is designed to allow maximum interaction and education between customer and barista.

4. You can set the espresso module to display temperature in Kelvin.

Okay, so it’s not actually that important that you can run the espresso module in Kelvin, unless you are the most awesome of nerds, but this little detail speaks volumes about the story and philosophy behind Modbar. To understand how, here’s a little background. Corey Waldron, Modbar’s founder, started in coffee as a barista and then roaster at Old Crown, which was Fort Wayne, Indiana’s first specialty coffee shop. Trying to introduce this market to specialty coffee, he was frustrated in his education efforts by what he felt like was a massive barrier between him and his customers: the espresso machine. So Mr. Waldron started dreaming of a machine that could “take the casket off the counter”, in his words. Building on his former career as a CAD designer for industrial chemical dispensing systems, he began work on the Jet Steam Ai-1, the first under-counter espresso machine that showed as a prototype at the 2007 Long Beach SCAA. The Ai-1 never made it to market, but it set the ground for the founding of Modbar. Corey worked on Jet Steam with Aric Forbing, a long-time friend and former bandmate, and Aric now helps with the design and manufacturing for Modbar at their assembly plant and CNC mill in Fort Wayne, IN, where 90% of the machine is made. Kelly Traw was brought in by investors at La Marzocco to handle the business and marketing side.

Yes, that La Marzocco. La Marzocco and Marco Beverage Systems are the principle investors in Modbar and have provided substantial input and support throughout the project. Scott Guglielmino, Product Manager for La Marzocco, helped out with the development of the spec for the machine, and because he is a huge nerd, he pushed for the ability to run the machines in Kelvin.

Actually adding Kelvin temperature display to the Modbar was easy because of the extensible design philosophy and the custom-built PIC32 software/controller platform. The radical physical design is the attention-getter, but the controls and internals of this machine are just as cutting-edge.

Programming and information display happens on a 3.2 inch full-color touchscreen. One touchscreen controls all connected modules. It sounds like a lot of thought has been put into making the software easy for baristas to use while giving them complete access to the machine’s temperature control and pressure profiling.

On the espresso module, 1 degree F temperature stability is achieved by an actively heated stainless steel thermoblock grouphead fitted with a La Marzocco portafilter, which is paired to a system that combines a highly reactive inlet boiler with a more fine-tuned outlet boiler. This system is used on both the espresso and pourover modules and allows for continuous temperature-stable operation with no recovery time, even when the taps are mounted as far as six feet away from the under-counter modules.

Full pressure profiling and volumetric functions are accomplished by a flow-meter / gear pump combination similar to the La Marzocco Strada EP. Corey says that he’s longtime friends with many of the people on the Strada team, and they were all working on similar ideas at the same time. The Modbar system makes use of its custom controllers to “smooth out” the gear pump operation, cutting down on the jumpiness that can happen with pressure profiling. I’m particularly excited that it sounds like the volumetric capabilities of the Modbar are more accessible than the Strada: volume is displayed on the tap head as shots pull, and you can set a volume cut-off that will interrupt any programmed profile.

By manipulating the three way actuator switch on the espresso tap, you can engage a custom profile, have it operate as a classic short pre-infusion / full pressure system, or activate the built-in self cleaning cycle. Profiles themselves are programmed in on the touchscreen by changing variables for max pressure and the times spent at line pressure, full pressure, and ramping up and down. The software smooths it all out and gives you a visual representation of the resulting curve. Though I love the romance and intuitive feel of more physical paddle-based approaches, this whizbang software sounds like a powerful way to approach pressure profiling.

The steam module is fairly straightforward. A 4.7L boiler provides heavy duty performance capable of running one or two steam wands. The module uses a hybrid actuation system with a mechanical dispensing valve on the tap for pressure control, and a electro-valve on the boiler. This system is setup so that the line is purged and kept empty when not steaming, keeping things nice and clean.

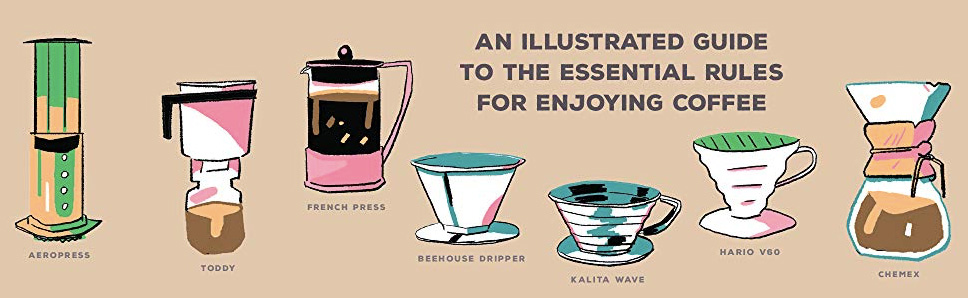

The pour-over module is the biggest question mark for me. It bears some similarity to Marco’s Uber Pillar in that it has a dispensing “wand” attached with a braided line. This wand is paired with a mounting system for brew devices inspired by a chemistry lab rod mounting system. The system is designed to fit multiple brew devices, and you can change out the sprayer tip on the wand for different spray patterns. You can use the wand freehand or rest it on the mounting system, and operation is based on pre-programmed volume and time based profiles. The system sounds functional and like a great companion to the other modules, but Modbar will face stiff competition differentiating themselves in the rapidly expanding pour-over brewing machine market.

One thing that does really differentiate the Modbar system are its power-saving features. Corey designed the system to be able to be turned on and off without issue, and when you turn the system on, it takes only five minutes for the espresso module to come up to operating temperature. Even more impressively, the espresso module includes a standby mode that can be programmed to engage after a tap has been idle for a certain amount of time. In standby the boilers kick down to a lower temp to greatly reduce power consumption, but a flick of a switch returns the tap to operating temperature in 30 seconds. I think the inclusion of this functionality may prove to be one of the most important innovations of the Modbar system. The subject of turning machines off and powersaving has been fodder for a number of heated twitter discussions, and the SCAA Green Guide and other industry efforts clearly show that increased sustainability at the cafe level is a big concern.

Understanding the needs of the modern specialty cafe is clearly a big priority for Modbar. They’ve reached out to a number of companies for input, including Counter Culture, Intelligentsia and Stumptown (Counter Culture bought the first machine, and will be displaying it at their booth at the SCAA Event; it’s probably a safe bet you’ll see one in a new Intelligentsia location soon). A lot of work went into making the machines as indestructible as possible, and they focused on simple internal layouts and standardized mechanical components to make for easy repairs. Talking to Kelly and Corey, they both emphasized how important they saw the extensible, easily update-able design to be, and said that as they grow they really want to be learning from their customers and constantly responding to their needs instead of trying to dictate exactly how the machine should be used.

They’re going to be taking a careful approach to growing so they can provide a high level of service to their customers. They’ve already begun production, though their capacity is limited, so they will be putting together a production list of customers at the SCAA show. To start with, they will be selling directly and focusing primarily on US sales, though they do want to expand internationally with local service and sales partners. The single tap espresso module will cost $5,399, the steam module will be $3,995 ($685 for an extra steam wand tap), and the pour-over module will cost $3,687. These prices are just for the taps and the under-counter module—the taps can get mounted to the counter however you want, but Modbar will also have some pre-made driptray style drains for sale that are designed to integrate well with the system.

Now that you know everything there is to know about all the other details of the machine, please allow me some journalistic license to freak out about the form factor of the Modbar. Seriously, I have been having fever dreams of the kinds of cafes this could go in. I mean, first off it’s gorgeous. But if this system really works, it is going to change the coffee service game forever. Whole new service flows are possible, and the tap form-factor will be so much easier to integrate into alcohol bars and other food-service environments where counter space is at a premium.

Corey brought up the point that a lot of customers have no clue what actually goes in their cappuccino, that they’ve never seen an espresso shot pull or what is involved in making that happen. No wonder it can be so hard to convince them to spend $4+ for a cappuccino. The Modbar has the potential to break down the wall separating us from our customers and let us really show them what we do and why it deserves respect.

It’s also going to challenge us to really deserve that respect. With the customer able to see right across your drip tray, you’re going to have to keep that thing mighty clean. No more leaving dirty rags lying around or pulling shots into scuzzy demitasses either. My greatest weakness as a barista is that I make too much of a mess on bar, so the idea of a customer right across from me, with nothing but a skinny tap to hide behind is frightening. It also sounds like an exhilarating challenge.

When I go out and pay $12+ for a craft cocktail, part of the appeal of the experience is watching the bartender’s self-assured dance as they carve and crack ice, pour, muddle, stir, shake and strain. Watching them work, you feel you are in capable hands.

My hope is that breaking down the espresso machine wall between barista and customer will ultimately let us take better care of our customers by encouraging more organic, educational and rewarding connections across the bar. I’m so very excited to find out if the Modbar system is up to the challenge of helping us reach that goal.